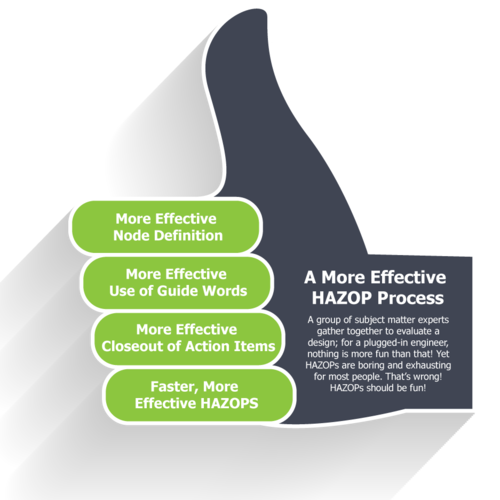

HAZOPs are not fun! Maybe that’s not a problem, but they also don’t achieve what they could and that is a problem. Why don’t we learn what we should from HAZOPs?

- Tunnel vision. The focus on small nodes obscures the big picture.

- Guideword excess – Flow, pressure, temperature, and level are usually discussed in the HAZOP. But flow deviations cause most pressure, temperature and level deviations.

- HAZOPs are supposed to identify operability issues, but they really don’t.

- Risk assessment in HAZOPs is typically difficult, ambiguous and not repeatable.

- HAZOP reports are difficult to read and are of limited use.

- Most people don’t enjoy HAZOPs and that impacts participation.

Our Stream-based HAZOP process avoids these pitfalls via some novel modifications to the process.

STREAM-BASED NODES

The main difference between the our Stream-Based HAZOP and a typical HAZOP is that we define nodes based on ‘streams’ for the FLOW deviation discussions. For this purpose a stream is a continuous flow of fluid across piping and equipment items. For example: oil production from the reservoir all the way to the dry oil tank can be considered one stream-based node. A change in flow anywhere in the node affects the flow everywhere, or at least downstream. This allows us to ask much more interesting questions that are hard to tackle in a typical HAZOP with small nodes. Issues like startup, shutdown, commissioning, sampling, chemical injection, spec breaks, recycle are much more meaningful at the stream-based level.

EQUIPMENT-BASED NODES

We do, however, have to resort to the typical equipment-based nodes for the temperature, pressure and level deviation discussions. But we do all the stream-based node discussion first and that populates almost all the causes of pressure, temperature and level deviation. So the pressure, temperature and level discussion are crisper and more efficient.