Preparing for operation of a major oil and gas facility is a daunting task. Prior to first oil we need standard operating procedures (SOPs), maintenance procedures, spare parts and trained operators just to name a few. And yet Operations Readiness efforts frequently start too late and are frequently inadequately resourced.

Operations Readiness systems developed late in a project and in silos can’t reach the potential of becoming the powerful tools that they were developed to be. This is the Industry Culture Change we have set out to implement. To change the Industry Culture of Operations Readiness, we changed the process and GATE mindset for development of ALL Operations Readiness Tools/Systems.

We provides the following services related to Operations Readiness:

- Operating Philosophy (Subsea & Topsides)

- Operability Reviews

- Standard Operating Procedures (SOPs)

- Initial Startup Planning and Procedures

- Operating Guidelines (Well, Subsea & Topsides)

- Pre-startup Safety Reviews

- Process Hazard Analysis (HAZID, HAZOP, SIL, LOPA)

- Maintenance Planning (CMMS, Spares)

- Spare Parts Data Development

- Equipment Criticality Ranking

- Reliability Centered Maintenance (RCM) Studies

- Failure Mode Effect Analysis (FMEA) Studies

- Innovative Operator Training (Scenario Games, Tactical Decision Games)

- Control System HMI Screen Development

- Control System Tuning (Based on First Principles – Not Short Cut Methods)

Standard Operating Procedures

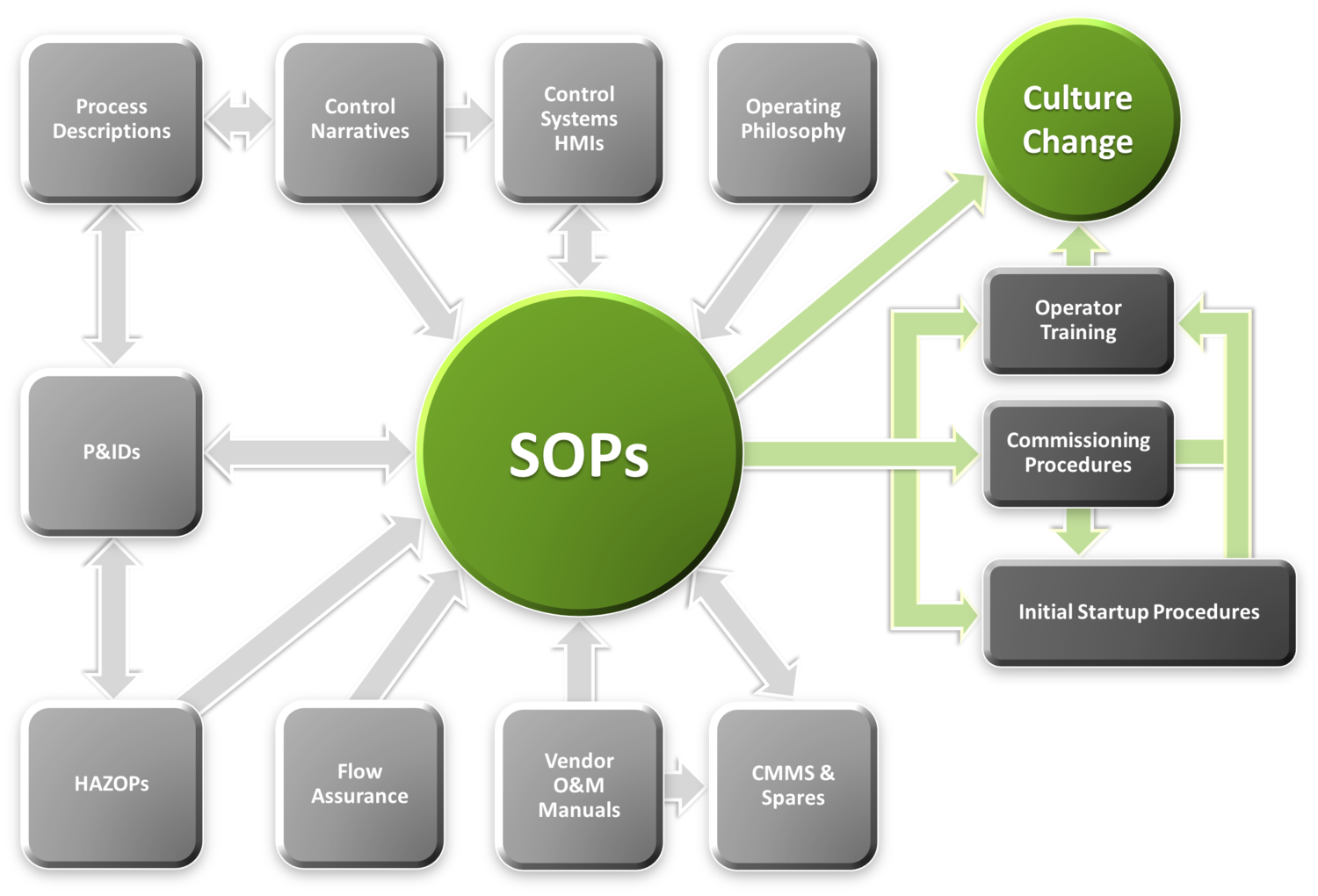

Of these, we consider Standard Operating Procedures (SOPs) to be particularly important. SOPs are frequently developed late in the project and used mainly for operator training. But they can be so much more. Generated early enough, they have the potential to be an integral part of the design process and to become a catalyst for a culture change. Generating SOPs early allows the rare opportunity to design a facility to be operated, as opposed to the current norm of figuring out how to operate a facility after it has been built.

We use an innovative phased approach. High level SOPs are developed early based on the PFDs. These are then matured to mid-level and finally to detailed procedures as the project matures.

Effective integration of the SOP development effort via a Systems Engineering Team yields other significant benefits. Coordination with the control systems design efforts can provide valuable guidance to HMI design to mimic how the facility will be operated.

Effective SOPs can dramatically simplify the development of final commissioning and initial startup procedures.

The development of the CMMS and Preventive Maintenance Schedules is more effective if done concurrently with the SOPs. Maintenance tasks can be specifically created and scheduled to reflect the equipment’s planned operability. Spare Parts will be set with valid Min/ Max levels based on the scheduled maintenance tasks, possible unexpected corrective maintenance tasks and logistical hurdles which may require to be overcome.

These are all powerful arguments to put more effort and earlier effort into SOP development, but we seek a still higher goal – Culture Change. Effective SOPs that are diligently used by operators may be the driver for the next step-change in process safety in the industry. But this cannot reasonably be accomplished unless we start writing procedures that are more user friendly; procedures that the operators will actually want to use.

Our Stream-Based HAZOP Process

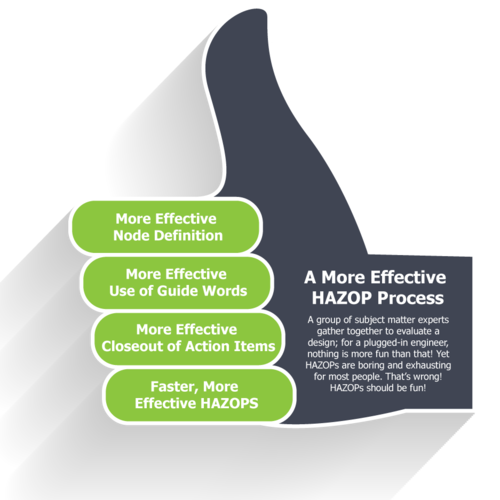

HAZOPs are not fun! Maybe that’s not a problem, but they also don’t achieve what they could and that is a problem. Why don’t we learn what we should from HAZOPs?

- Tunnel vision. The focus on small nodes obscures the big picture.

- Guideword excess – Flow, pressure, temperature, and level are usually discussed in the HAZOP. But flow deviations cause most pressure, temperature and level deviations.

- HAZOPs are supposed to identify operability issues, but they really don’t.

- Risk assessment in HAZOPs is typically difficult, ambiguous and not repeatable.

- HAZOP reports are difficult to read and are of limited use.

- Most people don’t enjoy HAZOPs and that impacts participation.

Stream-Based Nodes

The main difference between our Stream-Based HAZOP and a typical HAZOP is that we define nodes based on ‘streams’ for the FLOW deviation discussions. For this purpose a stream is a continuous flow of fluid across piping and equipment items. For example: oil production from the reservoir all the way to the dry oil tank can be considered one stream-based node. A change in flow anywhere in the node affects the flow everywhere, or at least downstream. This allows us to ask much more interesting questions that are hard to tackle in a typical HAZOP with small nodes. Issues like startup, shutdown, commissioning, sampling, chemical injection, spec breaks, recycle are much more meaningful at the stream-based level.

Equipment-Based Nodes

We do, however, have to resort to the typical equipment-based nodes for the temperature, pressure and level deviation discussions. But we do all the stream-based node discussion first and that populates almost all the causes of pressure, temperature and level deviation. So the pressure, temperature and level discussion are crisper and more efficient.

Initial Startup Planning & Procedures

Our initial startup planning involves incorporating the subsurface, subsea, and topsides aspects of the project, so eliminating any and all potential gaps.

The initial startup of a production system is one of the most challenging periods in field life; it is the first time the whole system has to work together. We believe development of effective planning strategies will minimize the risks. We have a broad knowledge in generating plans for the initial startup of wells, subsea tie-backs and new platforms.

Our engineers have extensive experience in writing commissioning, initial startup and operating guidelines and procedures. During the procedure writing effort, design errors and omissions are frequently discovered. In order to eliminate these problems, We believe that procedure writing should be handled in stages, begin early in the project and start as a high level procedure that gradually matures along with the design. Processes should be designed to be operated; operation shouldn’t be an afterthought.

Keys To A Successful Initial Startup

- Start Early: Planning For Startup Should Start Early In The Project

- Use A Multi-Disciplined Team

- Use A System Approach

- Build The Plan In Stages

- Risk Management

- Training

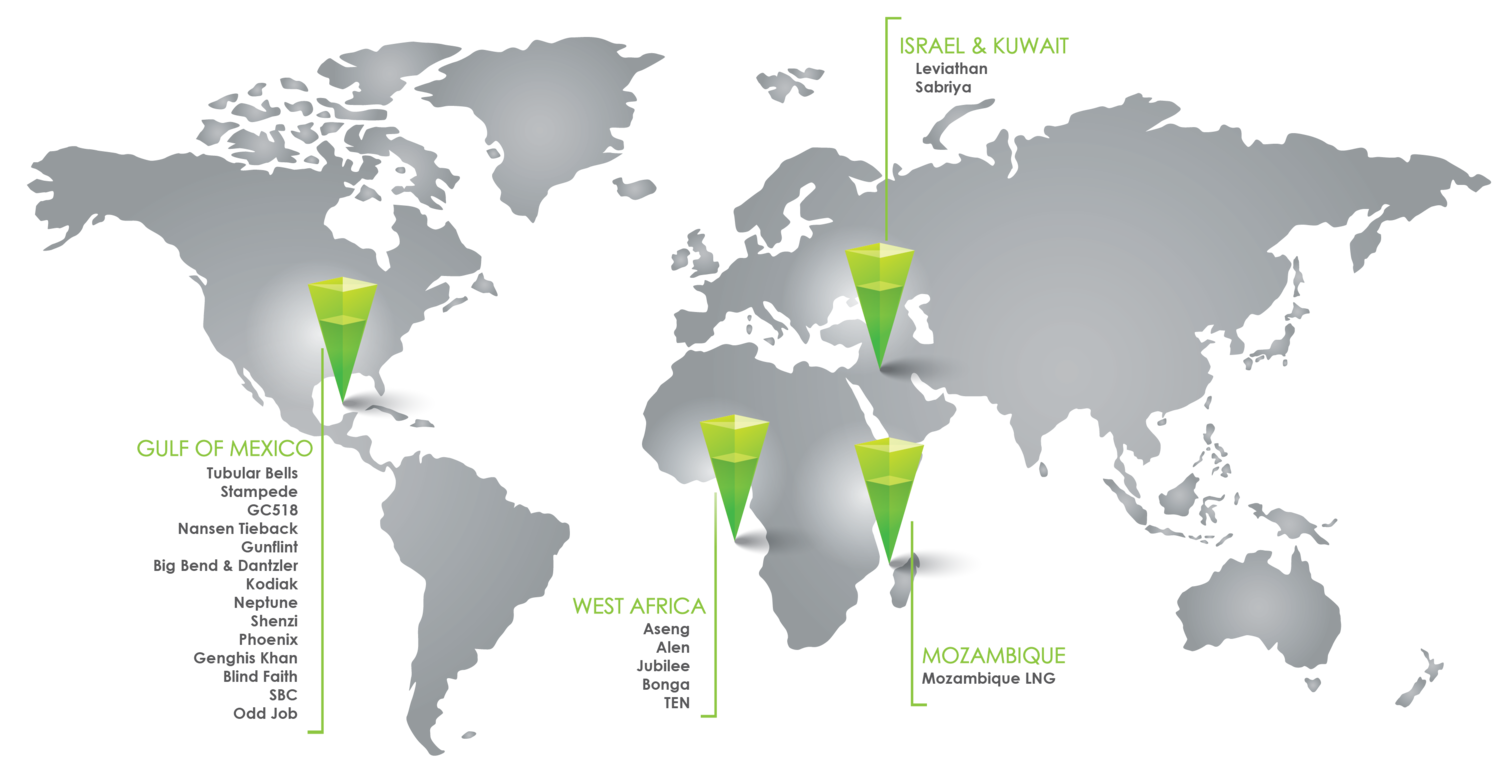

Recent & Key Projects Involving Operations Readiness & Initial Startup