ALPHA ENERGY’s capabilities in materials and corrosion engineering are well recognized within the industry and have played key roles in hydrocarbon developments worldwide.

The Corrosion, Materials and Integrity Team for oil and gas developments and water and gas injection systems forms one of our core oil and gas engineering services. The Corrosion, Materials and Integrity Team is involved at all stages of project development (Concept to Operations) and offers a significant interface with chemical systems engineering, flow assurance, operations, installation, and surveillance teams.

Our Corrosion, Materials and Integrity Team team develops whole-life cost solutions to corrosion and materials issues in the areas of:

- Downhole & Subsea Materials Selection and Qualification Erosion/Corrosion Risk Assessment and Modeling Scaling Studies (Formation Risk, Removal and Mitigation Strategies)Failure Analysis Protective Coatings and Cathodic Protection System Design Monitoring And Inspection Strategies During Field Design

- Topsides Materials Selection including Protective Coatings, Cathodic Protection Systems, Corrosion Monitoring, and Erosion Monitoring Systems

- Inspection and Auditing During Fabrication And Vendor Qualification

- Including Welding, Coating, Anode Chemistry, Positive Material Identification

- Pigging Solutions for Deepwater Production Flowlines and Risers Peer Review of System-Wide Materials Selections

- Linking Material Selection, Selection of Coatings and Field Joints Studies

- Risk-Based Assessment and Inspection Planning Troubleshooting Corrosion Problems on Operating Facilities

Material Selection

Our Corrosion, Materials and Integrity Team is involved with detailed material selection and qualification support with the goal of ensuring the selection of fit for service materials and their appropriate manufacture and fabrication. This work also ensures that designs conform to the latest codes and standards for downhole, subsea, and topsides equipment, while taking into account past project experience and industry best practice.

Corrosion Engineering Management

Material selection recommendations on a project are supported and supplemented by comprehensive corrosion, erosion, and souring reviews using various software packages. Our engineering support also extends to developing and coordinating corrosion testing and inhibitor qualification programs, to validate both material and chemical selection choices. This exercise also involves the recommendation, specification and commissioning of corrosion probes and sand monitors. In addition, the team extends its expertise to help develop and implement surveillance programs to ensure ongoing asset integrity through the life of the development.

Corrosion engineering management also extends to the troubleshooting of corrosion problems on operating facilities. This includes the management and mitigation of Carbon Dioxide (CO2), Hydrogen Sulfide (H2S) and microbiologically induced corrosion (MIC) modeling and failure mechanisms.

Coatings and Cathodic Protection

We provide detailed engineering support for coating selection and cathodic protection design. This also includes the qualification of coating applicators and anode manufacturing facilities. Associated responsibilities include supporting flowline and equipment installations for deepwater facilities and the post‐installation surveying of equipment.

Risk Based Assessment & Inspection

We provide risk based assessment and inspection services for its clients on various stages of the project by pursuing a systems engineering approach to the problem. This includes the development and oversight of risk‐based inspection (RBI) programs and the detailed selection of appropriate condition monitoring points and surveillance locations. Although we are familiar with the API approach to RBI, we have developed a streamlined in‐house methodology that enables RBI programs to be developed in a much shorter timeframe with a documentation process that is fully auditable and traceable in the same way as the API approach.

Integrity Assurance

We provide integrity assurance support to its clients by using the principle of a systems approach that complements our engineering experience by considering systemic risks through equipment interactions and design analysis. Risk assessment is a key element in managing pipeline system integrity, which involves identification and management of the risks through development of an investigation, intervention, redesign and inspection plan.

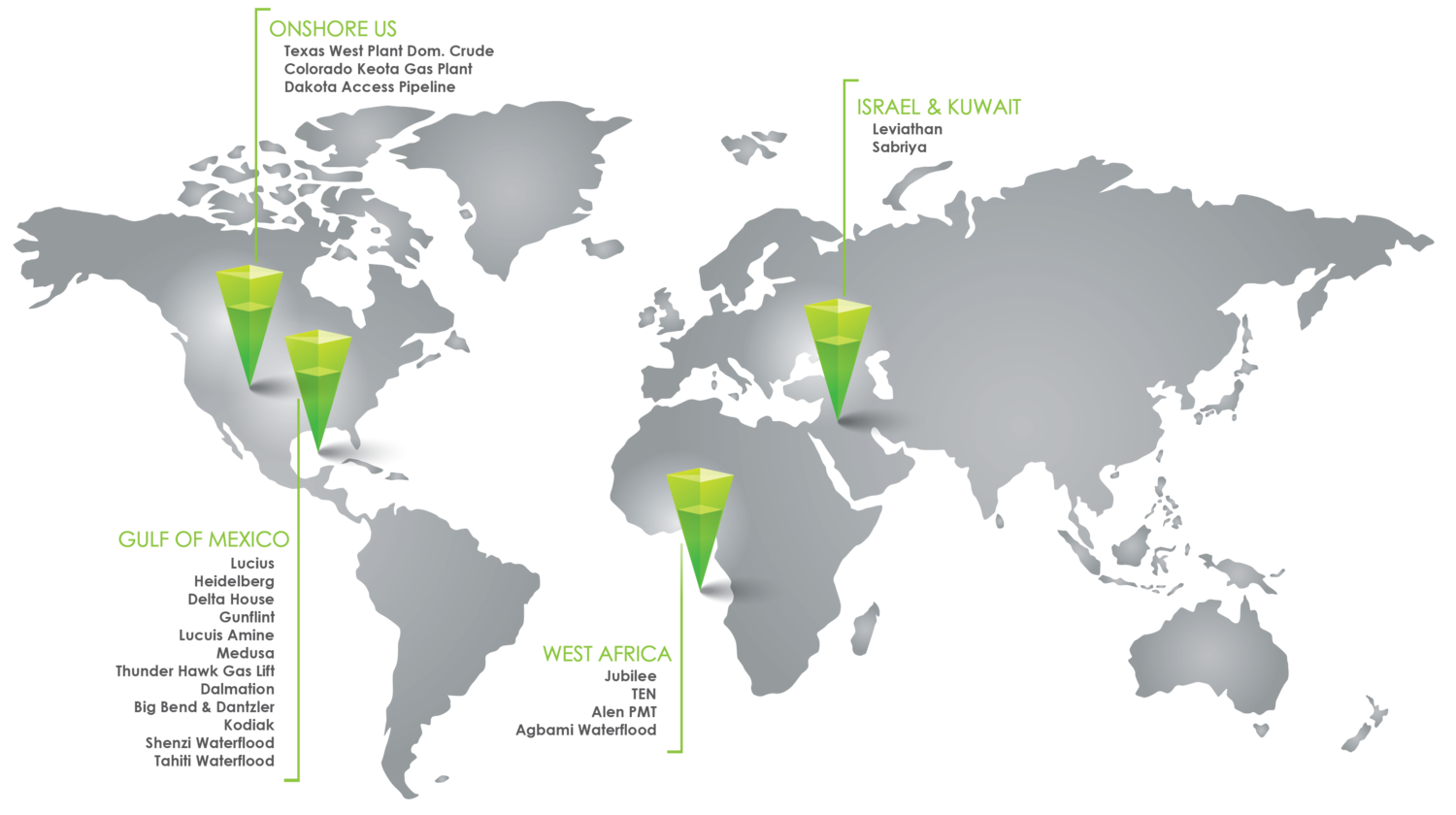

Recent & Key Projects Involving Materials & Corrosion

Our Corrosion, Materials and Integrity Team support a wide range of projects from conceptual, selection, design and fabrication though operations from small developments involving a tieback to large developments of an entire field.